Particularly with the integration of innovative technologies like 3D printing, the discipline of clinical engineering has experienced amazing progress over the past few years. Medical device design, prototyping, and manufacture have been transformed by this creative technology. 3D printing is becoming increasingly important in the medical device production process since it lets engineers design extremely accurate and customized devices in a fraction of the time and expense of conventional techniques.

The effects of 3D printing on medical device prototyping and production, its advantages for clinical engineers, and how it is changing the direction of healthcare will be discussed in this paper.

What is 3D Printing?

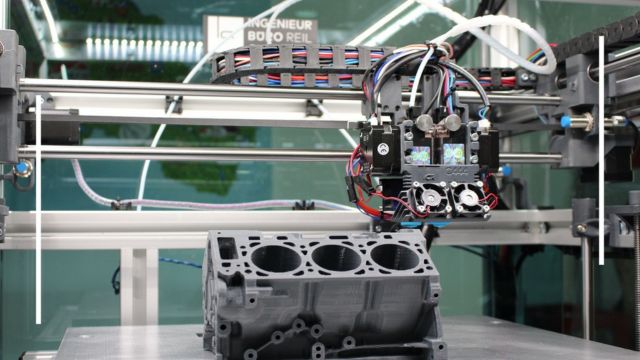

Using digital models, 3D printing—also known as additive manufacturing—allows layer by layer creation of three-dimensional objects. Although this technology is applied extensively in many different sectors, its value in clinical engineering and the medical device sector—where accuracy, adaptability, and fast prototyping are of great relevance—is especially clear.

Unlike conventional manufacturing techniques as injection molding or milling, 3D printing lets one create intricate shapes without using costly tooling or molds. This capacity to create complex and personalized patterns has made it a great instrument in the creation of medical tools like implants, prostheses, surgical tools, and diagnostic instruments.

You may like this: Cost Reduction Strategies Without Compromising Quality in Medical Supply Manufacturing

3D Printing in Medical Device Prototyping

Accelerating prototyping is one of the main advantages of 3D printing for manufacturing of medical devices. Especially for complicated devices, designing, building, and testing prototypes in conventional manufacturing sometimes calls for weeks or even months. Clinical engineers can quickly test, iterate, and modify prototypes created in hours using 3D printing, therefore enabling rapid development.

Key Advantages of 3D Printing in Prototyping:

- Faster Development Cycles: 3D printing significantly reduces the time needed for prototyping, enabling faster design iterations and quicker product testing.

- Cost Efficiency: Traditional prototyping methods often involve expensive tooling, molds, and materials. 3D printing eliminates these costs, allowing for cheaper and more frequent prototype production.

- Customization: Engineers can create prototypes that are tailored to specific patient needs or preferences, such as custom implants or devices designed to fit a particular anatomical structure.

By providing a quick and cost-effective way to test different designs, 3D printing enables clinical engineers to refine and improve medical devices with greater precision and efficiency. This allows for more accurate devices that can better meet the needs of patients and healthcare providers.

3D Printing in Medical Device Production

While 3D printing has been used for prototyping for years, its role in full-scale production of medical devices is becoming increasingly important. In fact, several companies and healthcare providers are now using 3D printing for the mass production of medical devices, especially in fields like orthopedics, prosthetics, dental devices, and implants.

Benefits of 3D Printing in Medical Device Production:

- Mass Customization: One of the key benefits of 3D printing in production is the ability to customize devices for individual patients. For example, implants can be designed to precisely fit a patient’s unique anatomy, improving the effectiveness of treatment and reducing the risk of complications.

- Material Flexibility: 3D printing allows for the use of various materials, including metals, plastics, and biocompatible materials. This enables the production of devices that are durable, lightweight, and safe for patients.

- On-Demand Manufacturing: With 3D printing, manufacturers can produce medical devices on demand, reducing the need for large-scale inventory and storage. This results in a more efficient supply chain and less waste, which is critical in an industry where precision and timeliness are key.

- Design Innovation: 3D printing enables the creation of complex and intricate designs that would be impossible or too costly with traditional manufacturing methods. This opens up new possibilities for clinical engineers to innovate and develop cutting-edge medical devices.

Examples of 3D Printed Medical Devices:

- Custom Implants and Prosthetics: 3D printing enables the creation of implants and prosthetics that are tailored to an individual’s anatomy, improving fit and functionality.

- Surgical Instruments: Precision tools and instruments can be 3D printed to meet the specific requirements of a surgery, reducing the risk of errors and improving outcomes.

- Hearing Aids and Dental Devices: Devices like hearing aids, crowns, and dentures can be made more comfortable and effective through 3D printing, which allows for custom designs and precise fitting.

Future Implications of 3D Printing in Clinical Engineering

The use of 3D printing in clinical engineering is still evolving, and it’s clear that the technology will continue to play a crucial role in the future of medical device manufacturing. As the technology advances, we can expect even greater precision, efficiency, and customization in medical devices.

Challenges to Overcome

Despite its many benefits, 3D printing for medical device production faces certain challenges, including:

- Regulatory Hurdles: The FDA and other regulatory bodies must approve 3D printed devices before they can be sold, which requires thorough testing and certification.

- Material Limitations: While a variety of materials are available for 3D printing, there is still ongoing research into developing more biocompatible and durable materials for medical use.

- Cost of Equipment: While 3D printing can reduce manufacturing costs, the initial investment in 3D printing equipment can be high, especially for advanced technologies like metal 3D printers.

You may like this: Advanced Materials & Technologies Revolutionizing the Future of Medical Device Manufacturing

Conclusion

Already having a major influence on medical device prototyping and production, 3D printing has many advantages in terms of innovation, cost-effectiveness, and customising. Faster, more efficient treatments for patients all around the world will be made possible by the way clinical engineers design and manufacture medical devices as the technology develops.

Keep informed on the most recent developments in medical manufacturing and clinical engineering! At J&J Supplies, we are dedicated to provide you useful tools and knowledge so you remain leading edge in the healthcare sector. For professional insights and updates on medical technology and clinical engineering developments, subscribe to our newsletter.